Software Description:

HSMWorks provides a fully integrated CAMsolution for SOLIDWORKS®, allowing you to get up to speed andbecome productive within minutes using familiar tools andworkflows.

HSMWorks allows you to maintain full associativity between theSolidWorks model and machining. Design changes in the CAD model getautomatically updated in downstream data such as drawings andtoolpaths.

The HSM Advantage:

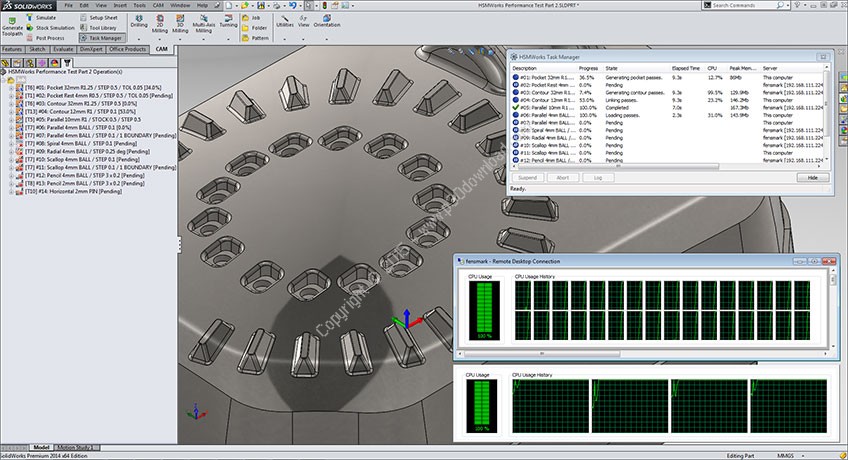

Modern architecture:

Take advantage of latest workstation technologies to achievesuperior performance, especially when working on large or complexdesigns. Multiprocessor/multicore support speeds up toolpathgeneration on supported hardware. The distributed CAM servermaximizes your computing power using idle PCs on the local networkto reduce toolpath calculation time.

Adaptive clearing:

This advanced roughing strategy provides efficient, high-volumematerial removal using constant tool engagement and optimizedcutter paths.

HSMWorks Edit:

Take advantage of several CNC code-specific functions, includingline numbering/renumbering, XYZ range finder, and file compare.Features a DNC link for reliable RS-232 communications with avariety of CNC controls.

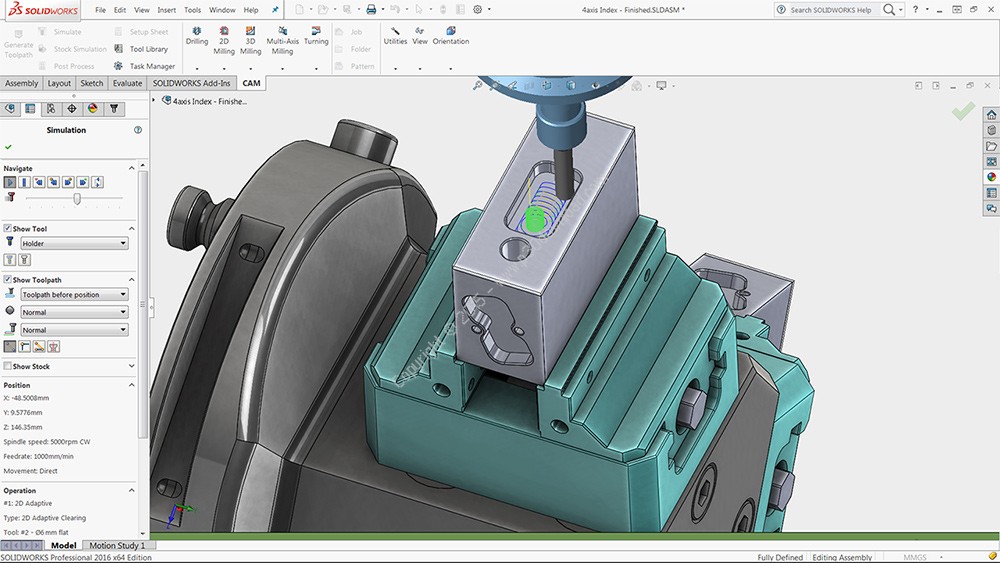

Simulation and Verification:

Visualize material removal using interactive animation withHSMWorks advanced simulation and verification tools. Ensureaccuracy of results even before cutting metal, boostingproductivity and cutting down material waste.

Stock and toolpath simulation:

See stock being removed and automatically check for shaft andclamp/fixture collisions. Easily inspect generated toolpaths withthe integrated backplot and inspection tool.

Milling machine simulation:

Machine simulation detects collisions and near misses between allmachine tool components such as axis slides, rotary tables,turrets, spindles, tool changers, and fixtures. HSMWorks uses aSOLIDWORKS model of your machine tool to detect potentialcollisions, making it easy to modify or build new machineconfigurations directly inside SOLIDWORKS.

2D / 2.5D Milling:

2D machining can range from very basic to highly complexoperations. HSMWorks solutions include the tools you need forprecise control over all aspects of 2D machining, including leadin/out and transitions between passes.

Contouring:

Control lead-in and lead-out with or without tool compensation.Choose multiple roughing and finishing passes and multiple depthcuts for any contour. Machine open and closed contours withoutcreating additional geometry, and eliminate sharp motion withcorner smoothing.

Drilling and hole making:

HSMWorks includes powerful tools for generating drilling,counterboring, and tapping operations. Both standard and customizedcycles are supported for all point-to-point operations, includingspot-drilling, deep drilling with chip break, and boringcycles.

3D, 3+2 and 5-axis

Best-in-class 3D strategies:

HSMWorks strives to generate the shortest and smoothest toolpathspossible, resulting in reduced machining time, improved surfacequality, less tool wear, and extended machine tool life.

3+2 machining:

Select a work plane for the operation, and HSMWorks generates themost efficient rotations to orient the part. All machiningstrategies are available once parts are positioned. Tools andholders are gouge protected for all strategies that normallysupport this feature.

5-axis milling:

HSMWorks includes advanced 5-axis features include swarf formachining using the side of the tool, multiaxis contour formachining along a contact curve, multiaxis flow for using tooltipalong a surface, and 3D toolpath tilting to reach deep cavity areasand small radii.

Turning and Mill-Turn:

Whether you are looking for a CAM system to help you improve yourproductivity with traditional turning operations like roughing,grooving, or finishing – or you want to start taking full advantageof your multi-axis machine tools, HSMWorks offers an intuitiveapproach to creating high-quality turning toolpaths.

Installer Size: 605 MB

Download Links : Autodesk HSMWorks 2018 R3.42230 x64 for SolidWorks + Crack