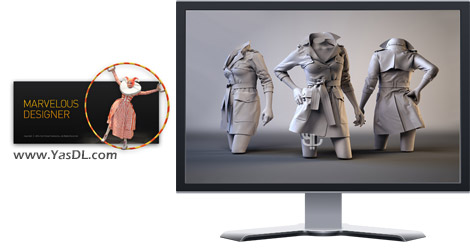

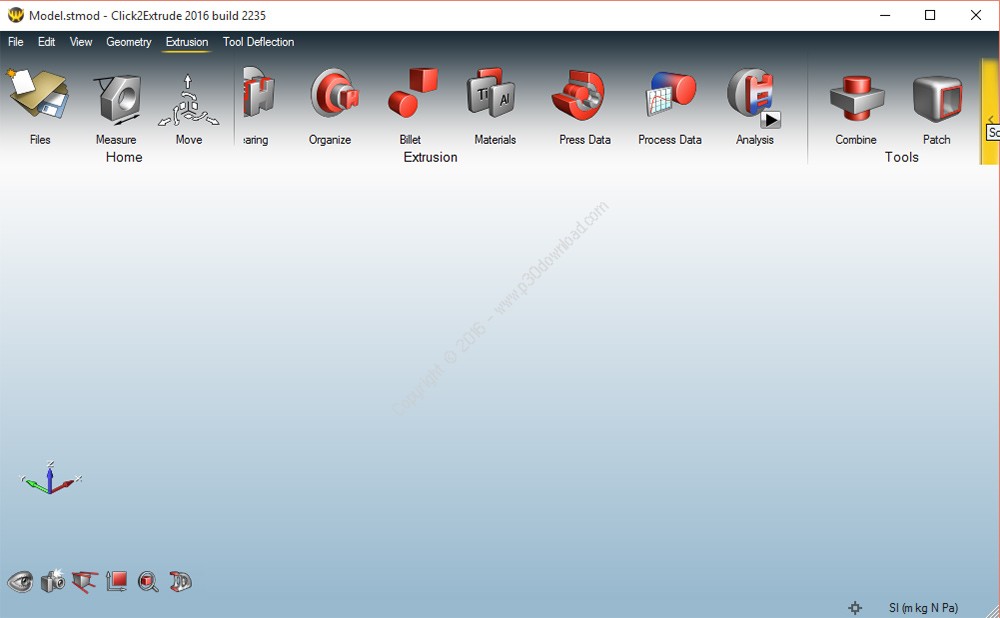

Software Description:

Today’s extrusion companies are required to coextrude profilesmade of multiple polymers with metal inserts in shorter productdevelopment cycles while simultaneously reducing their productioncosts. Click2Extrude is a simulation tooldeveloped to analyze and validate the design of these coextrusiondies and process.The HyperXtrude solver enables productionengineers to analyze material flow and heat transfer inside a dieduring extrusion to validate die designs which in turn helps toreduce or eliminate costly and time. Click2Extrude is easy to useCAD based interface. You won’t be required to complete steps suchas meshing or boundary condition creation manually. All theseoperations are completely done in the background with no userintervention.

solidThinking Click2Extrude Metal andPolymer are simulation based environments designedto help metal and polymer extrusion companies meet the everincreasing demands to produce complex profiles with tighttolerances, quality surface finishes and high strength propertiesat reduced cost. Click2Extrude Metal and Click2Extrude Polymer arevirtual presses where users can visualize material flow andtemperature inside a die during extrusion and make necessarychanges to ensure balanced flow, while identifying and eliminatingproduct defects.

Choked Bearing

Click2Extrude can automatically handle bearing regions withchoke

Variable Bearing Start

Models with bearing starting at different Z coordinates (variablebearing start) is supported and this will require manualmanipulation of bearing region.

Charge Weld Analysis

With a click of a button, any model can be submitted for transientanalysis and charge weld analysis is automatically enabled.

Billet Skin Tracking

While creating the billet, a skin layer can be added with noadditional effort. This automatically enable billet skin trackinganalysis, which is used for predicting back end defects, buttlength, and any potential issues with the die design.

Starter Billets

Multi-cycle analysis with different billet lengths for each cycleup to five cycles. Tapered Billet HeatingClick2Extrude now supportsspecification of tapered heating: axial, lateral, and radial.Specification used can be different from cycle to cycle up to amaximum of five cycles. For axial taper, five linear taper zonesare supported.

Automatic Model Setup

You only work with the CAD model. The steps required to do thecomputational analysis of extrusion is completely handled in thebackground with no user intervention.

Coextrusion Analysis

Click2Extrude can help analyze extrusion of one or more polymers.Up to five coextrusion layers are allowed.

Metal Inserts

In this release, inserts are modeled as a process condition. Theinsert condition is specified on the interface at which the polymercomes in contact with the insert.

Symmetric Models

Click2Extrude enables you to take advantage of the model symmetryand model either a quarter or an half or any symmetric section ofthe model.

Material Models

Click2Extrude comes with a built in material database. It alsoenables you to maintain your own database by adding, modifying anddeleting material data in your own database. Commonly used polymermaterial models are supported.

Installer Size: 1065 MB

Download Links : SolidThinking Click2Extrude Polymer / Metal v2017 Build 2600 x64 + Crack