Software Description:

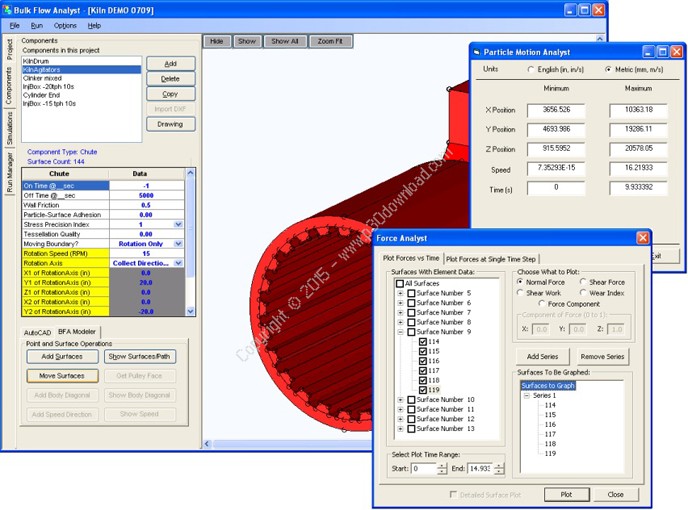

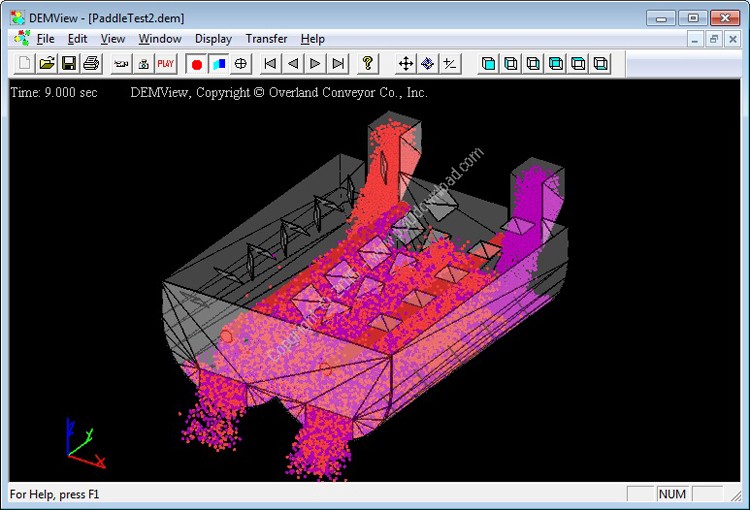

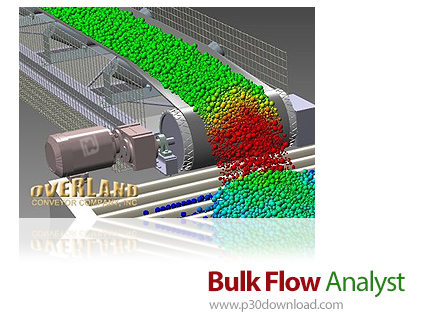

Overland Conveyor Company Inc. has released the BulkFlow Analyst is used to simulate conveyor transfer flow:Prevent Chute Plugging, Minimize Belt Wear, Minimize Chute SurfaceWear, Mimimize Dust, Minimize Spillage, Minimize MaterialDegradation.

Applied DEM is committed to providing bulk material handlingsolutions through use of our software backed by proven discreteelement method technology. We provide tools that aid in the designphase of bulk material handling problems. The use of oursimulations help identify potential problems before fullimplementation, saving our users time and money.

Bulk Flow Analyst™ is used to simulate conveyor transferflow

– Prevent Chute Plugging

– Minimize Belt Wear

– Minimize Chute Surface Wear

– Mimimize Dust

– Minimize Spillage

– Minimize Material Degradation

Features:

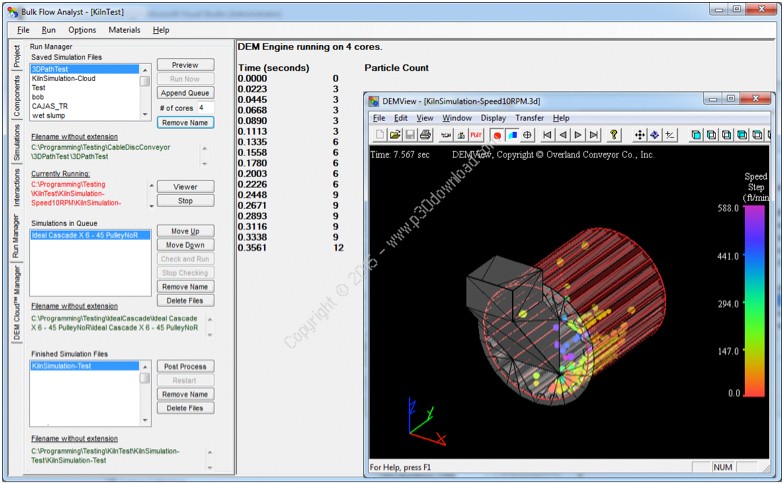

– Simulate particle flow with DISCRETE ELEMENT METHODS

– Cloud Computing makes this process VERY AFFORDABLE

– An international research team ensures GREAT TECHNOLOGY

– Developed BY ENGINEERS FOR ENGINEERS means: An easy to use”Virtual World” for designing your equipment

Past Bulk Flow Analyst™ users will not notice much difference inthe pre and post processing tools, but the performance of theexecution engine will be significantly better.

This switch will give us access to:

– Efficient parallelization algorithms allowing multi-threadingexecution- This release will take us from a single processoroperation to 32 processors (LIGGGHTS researchers have been able toprocess large problems on up to 9000 simultaneous processors todate so we will have great opportunities to increase ourperformance even more in the near future).

– Multi-threading will allow us to effectively increase the numberof particles in a simulation from around 100,000 (a limit due tothe length of processing time) to over 1,000,000 particles. And wewill go much higher in the near future.

Bulk Flow Analyst 15.0 New Features:

Custom Clusters

Applied DEM introduced the ability to define clusters severalreleases back. Clusters give users the ability to define a particleshape that isn’t purely spherical which allows the geometry todrive how the particle moves. In previous versions of the software,users had to define multiple material condition components todefine multiple cluster shapes. Each time an injection box wasadded to a simulation, users would have to add each of the materialconditions and apply the approriate breakdown of mass contributedby each material condition. Starting in version 15.0, users candefine multiple cluster shapes in a material condition, much in thesame way Custom size-distribution is used. The user specifies anumber of cluster shapes to use, then defines the shape and massfraction this shape contributes to the material.

Particle Blocks Allow More Materials

Prior to BFA 15, Particle Block components (Uniform nor Random)could not accept a material condition with a material size range.Particles had to be uniformly sized. For Random materials, thismeant that the Min and Max size had to be equal. Custom materialswere simply not allowed. Clusters were not allowed at all.

Now users of Random particle blocks are able to use materialconditions with a size range. Random materials and Custom materialswith size ranges can be generated within a particle block. Randomparticle blocks can also accept material conditions generatingclusters, whether those are custom clusters or not.

Motion Manager Makes a Strong Comeback!

Users of BFA prior to version 14 were able to use a tool called theMotion Manager, which allowed users to define complex movements forcomponents. Components were able to move and rotate, stop, reversedirection, and easily link one component’s motion to another movingcomponent (think leg-bone connected to the thigh-bone). This toolsimplified the definition of common components like flop gates anddump bodies that remain stationary, then rotate, then remainstationary again. However, it also allowed for the definition ofmore complex motions, such as bucket wheels rotating on two axes.Due to the change of numerical engines, BFA version 14 did notinclude the Motion Manager. But it’s back!

Enter the value of your component’s surface ID on the center right,then use the translation, local rotation, and global rotation tabsto specify distances and angles traveled in a given time range.Enter negative distances to move backward, overlap motions, linkthis component’s motion to another moving component, thepossibilites are nearly limitless. Click “Save Files” and run yoursimulation as usual. You can simulate extremely complex motions,all the while BFA will be determining how these motions affect theflow of your materials.

Installer Size: 201 MB

Download Links > Bulk Flow Analyst v15.0 + Crack