Software Description:

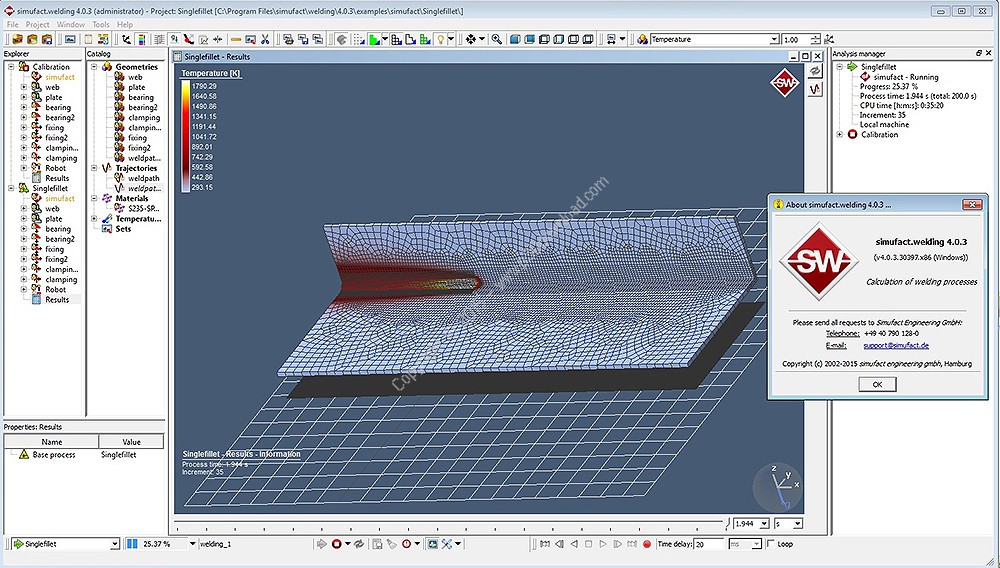

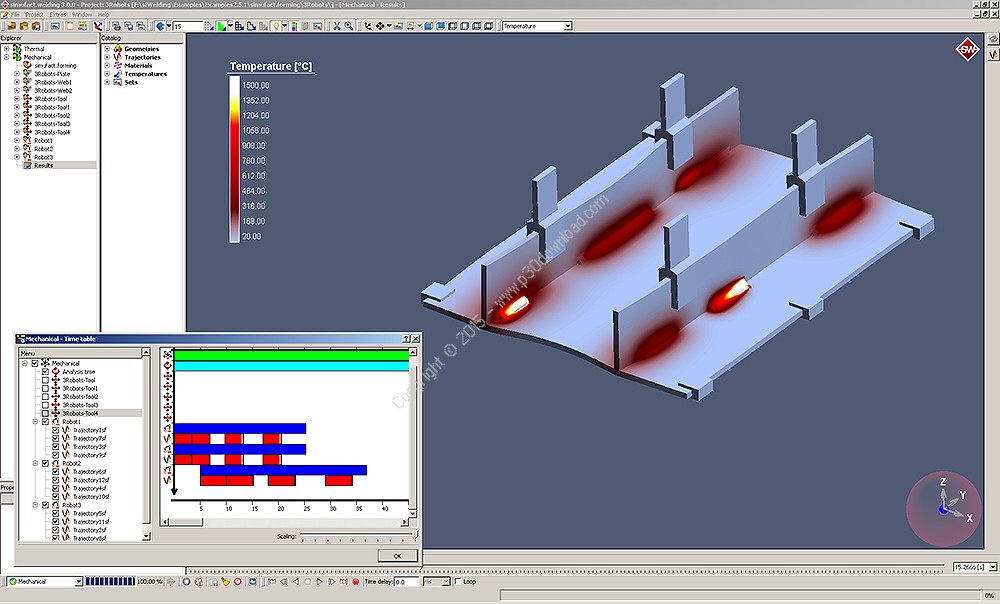

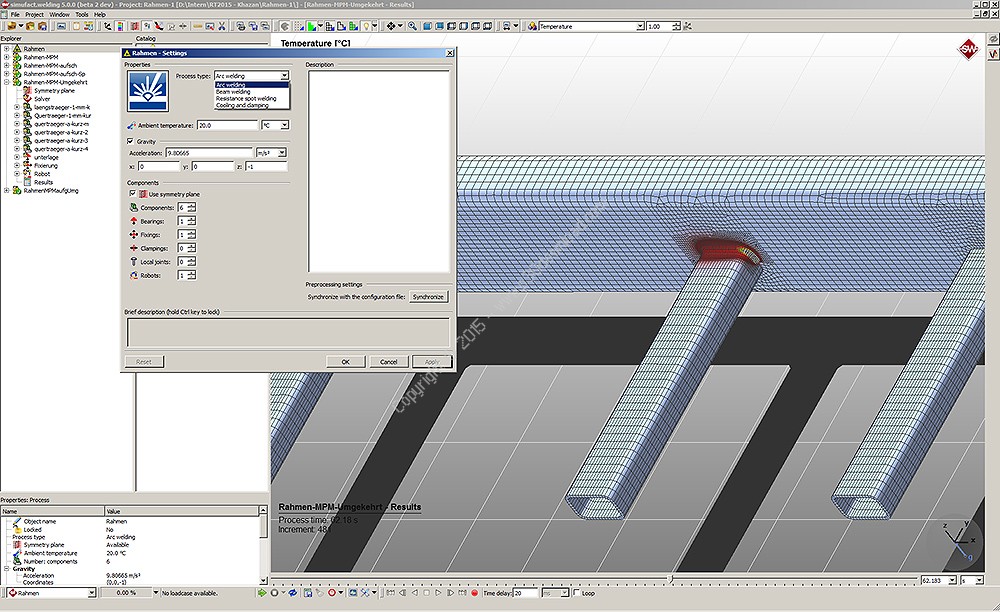

Nowadays industrial welding processes require a high degree ofprocess security. The correct design of a welding procedure sheetis essential for the quality of a process, which is needed for theprogramming of welding robots among others. The correct applicationof clamping devices, the employed welding process and the energyinput are added. Distortions of the final geometry must be fullycontrolled so that components can be serially produced with precisetolerances. Knowledge about the kind of the heat influence zoneenables specialists to conclude the properties of welding seams.Simufact welding is a Finite Element-based programfor welding simulation. Finite Element calculations are suitablefor modeling the elastic-plastic material behavior and, thus, alsofor simulating welding structure.

Latest solver technology and a user-friendly overall conceptallow to calculate welding sequences efficiently and to predictdistortions of the component realistically, also with regard tomicrostructural changes.

A new element is the coupling of Simufact.welding withSimufact.forming and, hence, the combination of various processchains. Thereby, up- and downstream processes of the welding can beefficiently integrated into the numerical simulations. The simpledata transfer allows not only the consideration of the forminghistory but also the strength analysis of simulated weldingseams.

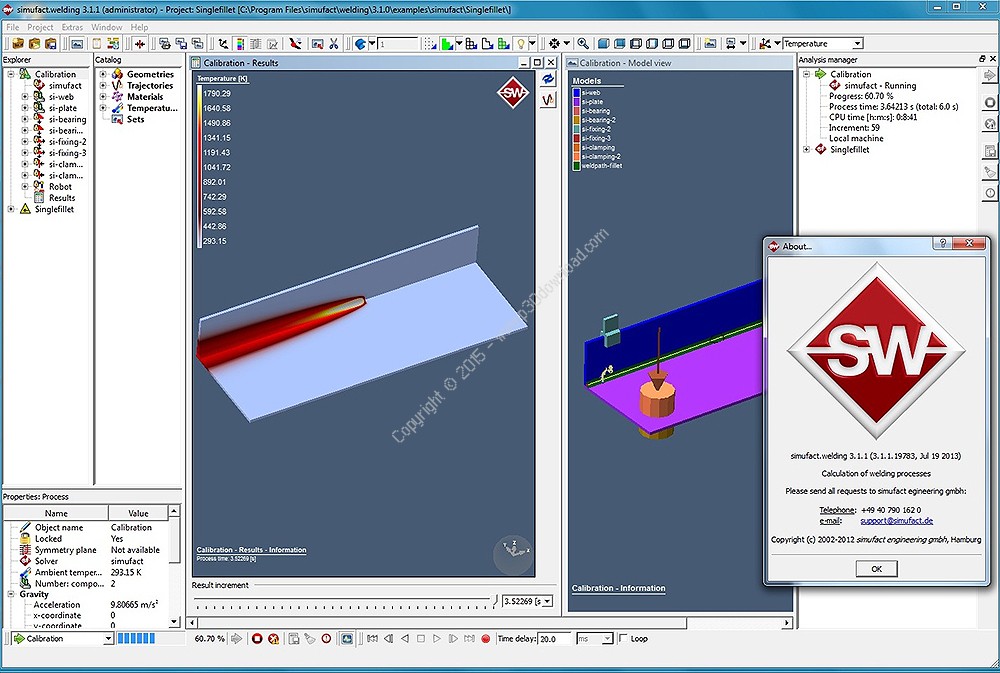

Simufact.welding allows the calibration of combined alternativeheat sources in less than 15 minutes. It provides useful tools tothat end.

Alternative heat sources are general state-of-the-art in simulatingwelding structures The question “Which welding processes arecompatible with your software?” becomes secondary, since almost allcommon methods can be depicted by means of alternative sources.

The aim of a calculation with Simufact.welding is the prediction ofwelding distortions and internal stresses. By the standardimplementation of material models, e.g. from Simufact.premap, alsomicrostructures, material conditions and resulting local materialproperties can be calculated.

Here are some key features of “Simufactwelding”:

– pre- and postprocessing in one GUI

– graphically interactive control flow for robots and clampingtools

– sectional view for all earnings

– progress bar for calculation with access to results alreadycalculated during the analysis

– simultaneous evaluation of results during the calculation

– weldmonitor (journey through the welding joints in 2D-section

– diagrams with measurement points for the comparison with testwelds

Installer Size: 731 MB

Download Links > Simufact Welding v5.0 + Crack