Software Description:

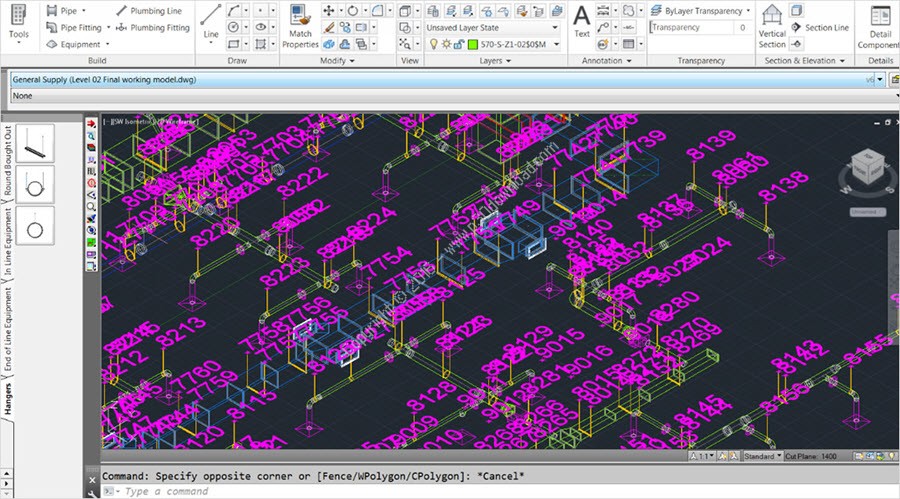

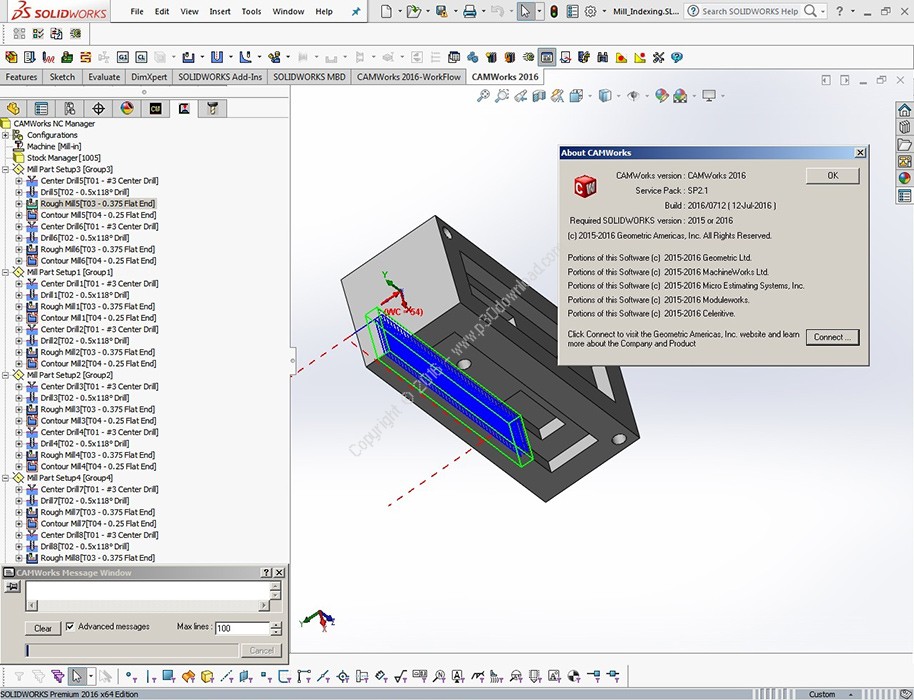

CAMWorks is an intuitive, feature-based CAMsoftware that helps to increase productivity using best-in-classtechnologies and adaptable automation tools to maximize CNCmachining efficiency.

Geometric has launched the 2015 version of its intuitivesolids-based CNC programming solution, CAMWorks. New releaseincludes numerous new features, enhancements and fixes for a numberof user-reported issues. CAMWorks 2015 also includes many otherimprovements that enhance overall ease of use and machiningcapability.

In previous versions of CAMWorks, the functionality to select asolid body as stock was available only in Mill Assembly mode. FromCAMWorks 2015 version onwards, this functionality has been extendedto Stock Manager dialog box of Mill, Turn, Mill-Turn and Wire EDM.You can assign either a desired SOLIDWORKS part file or anotherSOLIDWORKS configuration from the current part file as thestock.

In previous versions of CAMWorks, multi-surface features could beinteractively inserted by one of the following methods:

– By selecting part faces individually in the graphics area

– By selecting all the displayed faces

– By using an STL file.

From CAMWorks 2015 version onwards, multi surface features can beinserted by selecting faces of a particular color. This method isuseful when you assign specific colors to the surfaces to bemachined. When you select Faces by color as the Feature type in theNew Multi Surface Feature dialog box, you can create a multisurface feature by selecting surfaces based on their colors. Thesecolors and the number of faces with that particular color will bedisplayed in the Faces by Color group box. When the checkbox nextto a particular color is checked, the multi surface feature will becreated using faces with that color. You can select multiplecolors, if required

Tool Crib Priority Option for Turn andMill-Turn

CAMWorks is the ability to automatically assign tools to machiningoperations for each individual feature type. These rules areuser-defined and are specified in the Technology Database under theFeature & Operation menu. When the Tool crib priority option in theTool Crib tab of the Machine Dialog Box is selected, the automatictool selection rules are modified to place a higher priority onselecting tools from the tool crib. CAMWorks will consider all toolselection criteria (TechDB ID, Tool Type and Holder Orientation)and major tool parameters while selecting the tool from the ToolCrib. If an exact match isn’t found, then certain rules of the toolselection process (such as TechDB ID, Holder Type, Nose Radius,Include Angle) are relaxed. If a matching tool isn’t found in thetool crib even after relaxing those rules, then CAMWorks will addthe tool from the tool library.

Provide Rotary Axis mode options in TechDB for Milloperations

When the Machine type is set to Mill-Turn, for post processing andsimulation, it is imperative to indicate the Rotary Axis mode i.e.whether for a mill operation will be Fixed (XYZ) or Free (C-Axis”XCZ”). In earlier versions of CAMWorks, the provision to definethis method is available only in the CAMWorks UI (in the NC tab ofthe Operation Parameters dialog box) with “Fixed” being the defaultmethod.

Consequently, every time a Mill-Turn machine is used, if the userwants to assign “Free” as the default option, then he/she needs tochange the setting for every Mill operation by opening theOperation Parameters dialog for each Mill operation and changingthe Rotary axis mode in the NC tab. Such a task can get repetitivewhen Mill-Turn machine is frequently used. From CAMWorks 2015version onwards, the provision to set the Rotary Axis mode is madeavailable in the NC tab of the Operation Parameters Form for all2.5 Axis Milling Operations. This enhancement will enable the userto set the preferred Rotary Axis Mode option as the default,thereby eliminating the need to change the setting for every Milloperation in the CAMWorks UI.

Installer Size: 3077 MB

Download Links > CAMWorks 2018 SP2 x64 + Crack