Software Description:

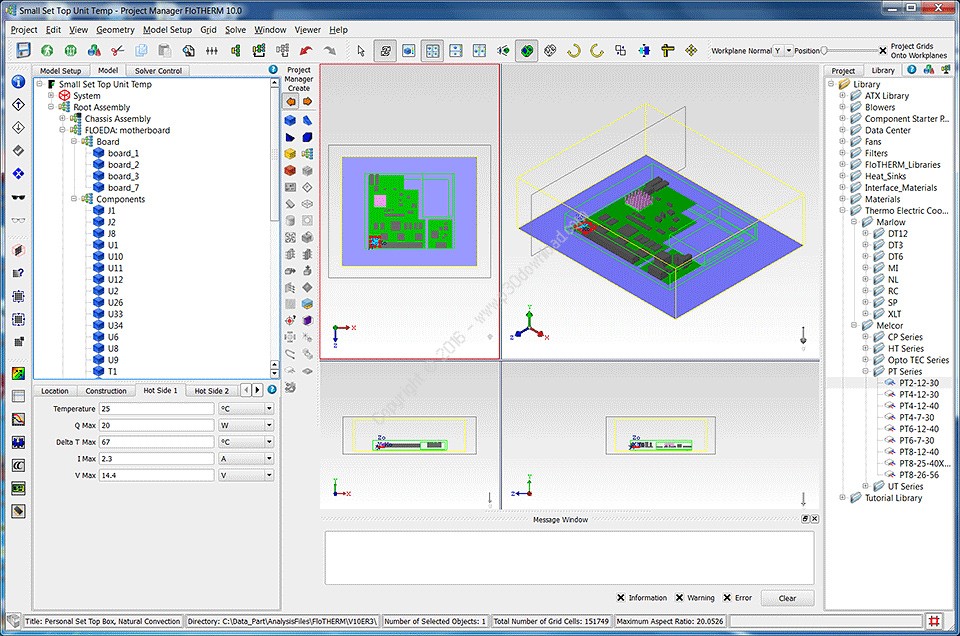

FloTHERM is the undisputed world leader forelectronics thermal analysis, with a 98 percent user recommendationrating. It supports more users, application examples, libraries andpublished technical papers than any competing product.

Accelerated Thermal Design Workflow

FloTHERM integrates with popular MCAD and EDA tools. Its XML importcapability simplifies building and solving models, post-processingresults automatically. FloTHERM’s automatic sequential optimizationand DoE capabilities reduces the time it takes to reach optimizeddesign, allowing it to be deeply embedded in the design flow.

Robust Meshing and Fast Solver

FloTHERM lets engineers focus on design, delivering the mostaccurate results possible within engineering timescales. ItsSmartParts and structured-Cartesian method offers the fastestsolution time per grid cell. The FloTHERM “localized-grid”technique supports integrally matched, nested, non-conformal gridinterfaces between different parts of the solution domain.

Usability and Intelligent Thermal Models

Integral model checking in FloTHERM lets users see which objectshave attached material, the power attached to every object, andcorresponding assembly-level power dissipation. It also identifieswhether the object is creating a mesh line.

FloTHERM SmartParts represent ICs to full racks of electronics froma large list of suppliers, streamlining model creation to minimizesolve times and maximize solution accuracy.

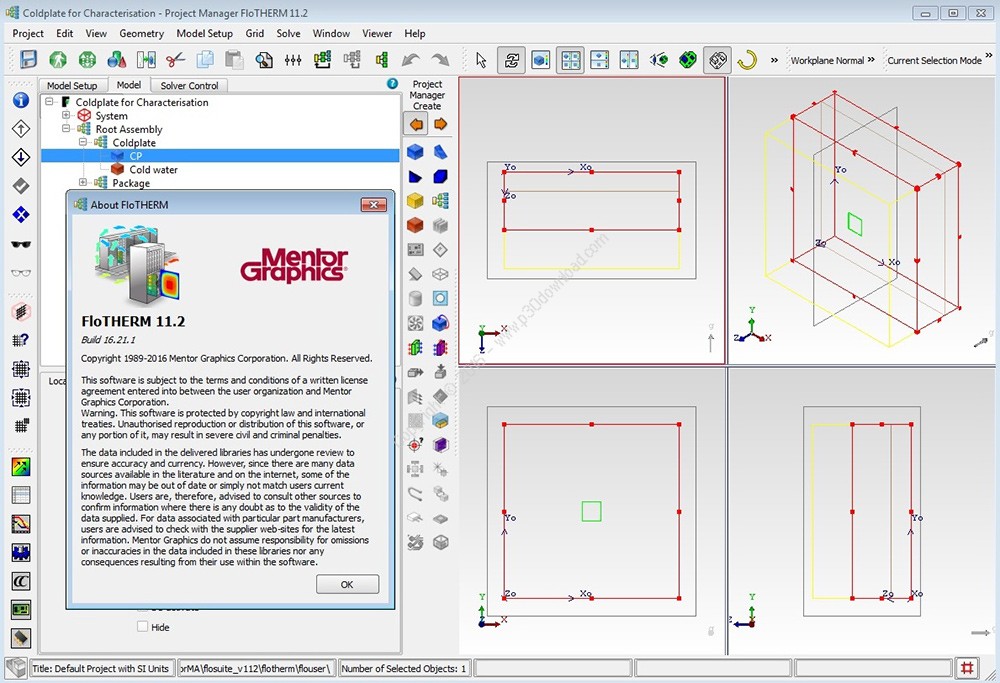

Thermal Characterization and Analysis from Component toSystem

Combine FloTHERM with T3Ster transient thermal characterization forthermal simulation of real-world electronics. Since reliability ofcomponents can decrease exponentially due to heat problems, usingT3Ster lets manufacturers design chips, ICs, and PCBs of superiorthermal performance. They can also publish reliable thermal datafor downstream applications.

Now FloTHERM can convert a simulated transient thermal responseinto a structure function curve using the same mathematical processutilized by T3Ster. These structure function curves are known tocorrelate with the physical structure of the device, and are thusthe ideal platform to compare simulation results with actual testdata. FloTHERM’s Command Center now provides automated calibrationof the package thermal model to match the T3Ster results, ensuringthe correct thermal response irrespective of the length of thepower pulse. Equipment manufacturers and systems integrators cannow use calibrated models to design even more reliable products,avoiding thermally-induced failures throughout the product’slifetime.

Installer Size: 1608 + 249 MB

Download Links : Mentor Graphics FloTHERM fth12.0 x64 + FloTHERM PCB ftp8.3 x86/x64 + Crack