Software Description:

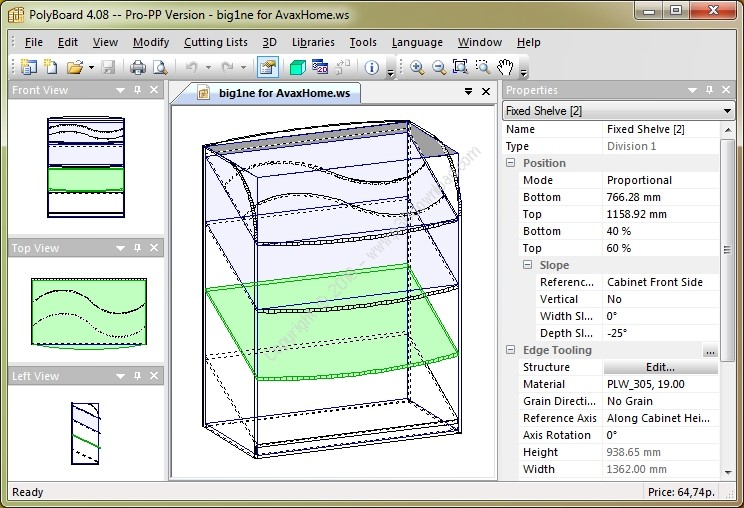

PolyBoard is an interactive design andmanufacturing cabinet software, based on a powerful methologicalconcept (BOOLE & PARTNERS exclusivity). PolyBoard supportsarborescent cabinet structures, dynamic material styles andmanufacturing methods lists, and recalculates cabinets in realtime. As modifications proceed, PolyBoard redraws the cabinet in 2Dand 3D, and recalculates its cutting list and toolings, in relationto:

The cabinet dimensions, including slopes and unboxings. Thedivisions structure (uprights and shelves), the doors and drawers.The manufacturing method : side master, top master, or mitre joint,applied, rabetted, or slotted back, recesses, overlaps, hardware,regular drilling groups (type 32), etc. The material, the edges,and the frames style of each cabinet component.PolyBoard supportsparametric fitting links, and edits a global hardware summary aswell as a tooling map (drillings and groovings) for each of thecabinet components.PolyBoard’s Post_Processing export function iscompatible with most CNC tooling machines.

– 2D & 3D Views

PolyBoard displays the three cabinet 2D views (front, top, andside), and a 3D rendering in relation to material colors andtextures.The PolyBoard built-in 3D function offers severalpredefined views, and various zoom and rotation tools, which helpsetting the wished 3D view. PolyBoard also offers a DXF 3D_Faceexport function, compatible with most CAD software, such asAutoCad, VectorWorks, KitchenDraw, etc.

– Slopes and Unboxings

With PolyBoard you may design :

Front sloped cabinets, up to 3 different angles in front view. Sidesloped cabinets. Rear left or rear right unboxed cabinets.

– Cutting Lists

PolyBoard cabinets cutting lists are recalculated in real time,taking into account specified materials, possible oversizings, andplated edges thickness. Cutting lists are exported in OptiCutformat, as well as in a «Text» format compatible with mostspreadsheets and cutting optimization software.

Material Styles

PolyBoard supports a dynamic material style list : A material styleassociates a different material to each cabinet component. Afterapplying another material sytle from the list, the cabinet isrebuilt instantaneously with this new style’s materials. The sameprinciple applies to edges styles.

– Manufacturing Methods

PolyBoard supports a dynamic manufacturing method list : Amanufacturing method defines all the geometrical and mechanicalcabinet assembly rules. A manufacturing method also specifieswhether the back is applied, slotted, or rabetted, determinesrecesses and overlaps values, and defines each of the fitting linkshardware type.

– Interactive Modifications

Once the cabinet is designed with a material style and amanufacturing method, a «double clic» on a cabinet component willallow its position, its material, or its edges modification. In thesame way, a «double clic» on a fitting link will allow its hardwaremodification.

– Toolings and Hardware

To each fitting link, PolyBoard manufacturing methods associates ahardware type and a positionning rule. Vertical divisions toolings(sides, uprights, and verticals) follow regular drilling groupsrules, such as type 32. PolyBoard edits a global cabinet hardwaresummary, and a tooling map for each of the cabinet components.

– Post_Processor

PolyBoard’s Post_Processor is compatible with most CNC toolingmachines. PolyBoard generates a parametric DXF format (colors, linestyles, and layer names), as well as WoodWop MPR (Weeke), XilogPlus XXL (SCM), BiesseWorks CID (Rover) formats.

Installer Size: 10.11 MB

Download Links : PolyBoard Pro-PP v6.04n + Crack