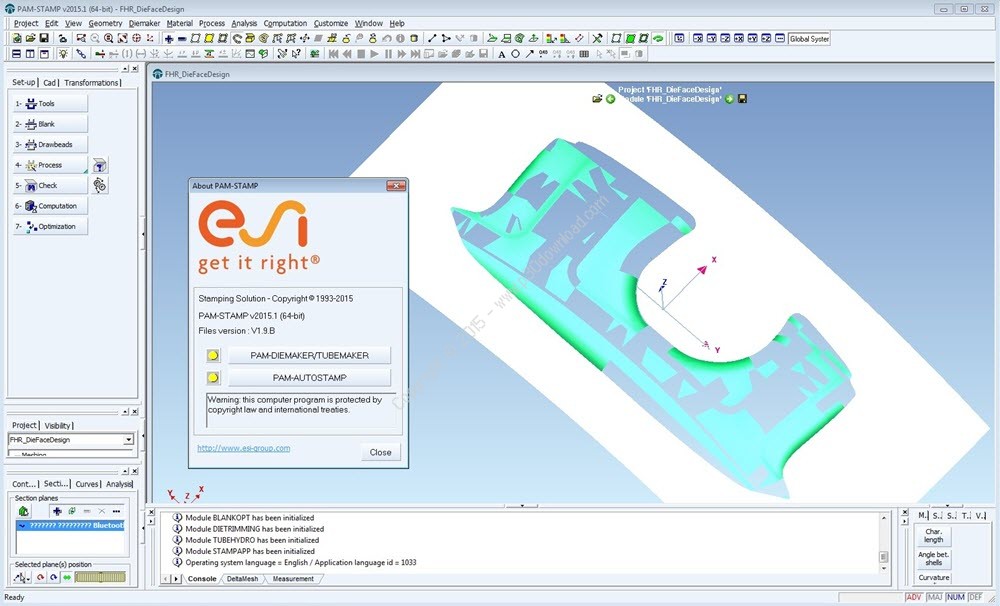

Software Description:

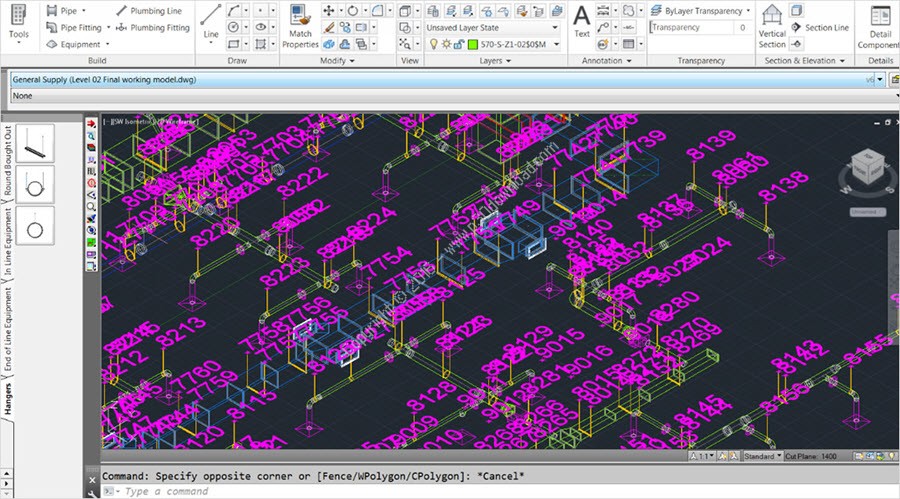

ESI PAM-STAMP is a complete, integrated,scalable and streamlined stamping solution. It covers the entiretooling process from quotation and die design through formabilityand try-out validation, including springback prediction andcorrection. It provides solutions-oriented tools for Automotive,Aerospace, and General stamping processes.

PAM-STAMP allows users to make decisions online, bringing togetherthe design engineer, the material provider, the die designer andthe try-out press shop from an early stage of the design rightthrough to production. This web-enabled technology allows images,annotation, text and 3D, models to be shared, thus supporting atruly collaborative engineering environment.

The release of ESI PAM-STAMP 2017 delivers major efficiencyimprovements for setting up progressive, transfer and line dies.ESI engineers have redesigned the User Interface (UI) in order tosignificantly reduce the number of “clicks” and drasticallyincrease work efficiency. Setting up processes is now done directlyfollowing a new and streamlined horizontal workflow, facilitatingthe setup of the entire stamping process; end to end.

ESI Group is a leading innovator in Virtual Prototyping softwareand services. Specialist in material physics, ESI has developed aunique proficiency in helping industrial manufacturers replacephysical prototypes by virtually replicating the fabrication,assembly and testing of products in different environments. Today,coupled with Virtual Reality, animated by systems models, andbenefiting from data analytics, Virtual Prototyping becomesimmersive and interactive: ESI’s clients can bring their productsto life, ensuring reliable performance, serviceability andmaintainability. ESI solutions help world-leading OEM’s andinnovative companies make sure that their products will passcertification tests – before any physical prototype is built – andthat new products are competitive in their market space. VirtualPrototyping addresses the emerging need for products to be smartand autonomous and supports industrial manufacturers in theirdigital transformation.

For any given metal forming process, it is possible today toconceive everything in a virtual engineering equivalent – fromdetailing customer requests to virtually inspecting the finalproduct, as well as setting-up the production facilities. Thisincludes material cost estimation, die design and feasibility, partdesign validation and tooling design and forming processes.

Making engineers productive – What is available and howdoes it work:

– Topology check, cleanup and repair

– Material cost estimation

– Die face design next generation based on B-Spline geometry

– Fast link with simulation

– Accurate numerical methods

– Geometrical drawbeads

– Springback – Kinematic Hardening Model

– Ironing

– Triple speed mode for breathtaking short simulation times

– Precise prediction of wrinkles including folding – no numericalflattening

– Blank & Trim Line Optimization

– Springback of High Strength Steel

– (Multi-operation) compensation

– Virtual prototyping of the full stamping chain

– Cosmetic defects

– Customization

– High quality results without tradeoffs in cost and time

– Hot Forming , End-to-End Virtual Prototyping

– Chaining with manufacturing engineering and assemblyprototyping

– Virtual Reality

Installer Size: 733 MB

Download Links : ESI PAM-STAMP v2017.0 x86/x64 + Crack